Leading the Way with Innovative Motor Repair Technology

Complete Electric Motor Services

The Brandon and Clark Difference

In today’s “commoditized” competitive landscape it can be hard to see what makes one solutions provider different from another. It might be tempting to go with the lowest bidder, right? Even though on the surface it might appear “all are equal,” that is far from the truth. When it comes to repair, quality control, repair methodology, testing capabilities, materials used, experience and repair equipment all influence the repairs at hand. Beyond our fundamental differences also comes the value we can add to your industry, business or process.

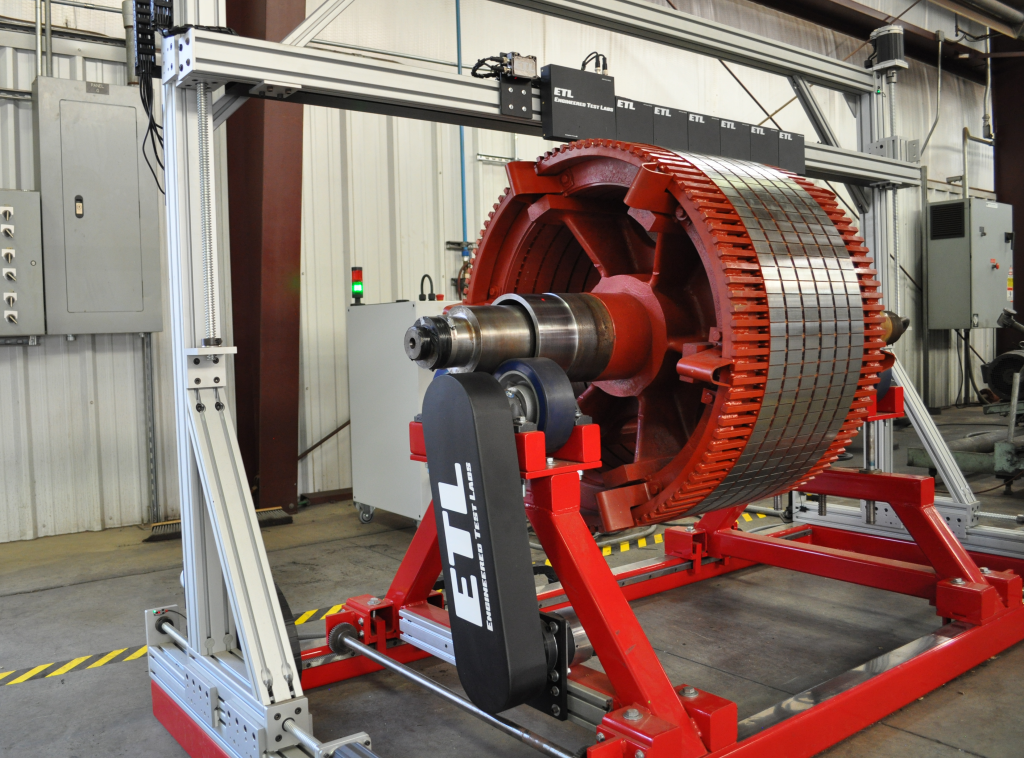

Rotor Testing Development and Innovation

- RMFA and sRMFA Technology was developed by Brandon and Clark’s staff of Professional Electrical Engineers

- Many current methods of rotor testing lack the sensitivity to detect rotor bar defects beyond major issues such as a broken rotor bar.

- Measuring the magnetic field of a rotor when excited from an external source allows for the detection of a wide variety of rotor defects such as brazed connection degradation, cracked rotor bars, broken rotor bars, and casting defects.

- This method of testing provides advantages over many current testing techniques in testing sensitivity, recording, reporting, illustration of machine condition to the end user, and testing safety.

Services that Get to the Root Cause of Failures

Motion Amplification – What you See Changes Everything. See the Problem, See the Solution. Motion Amplification is a service that utilizes patented technology to measure deflection, displacement, movement and vibration of equipment and structures not visible to the human eye. Utilizing a high-performance video streaming camera, in conjunction with one-of-a-kind software and processing algorithms, we are able to extract meaningful data that resolves problems.

Useful to:

- Identify

- Validate

- Specify the source of reliability issues

- Prioritize maintenance

From Preventative to Predictive Maintenance

Brandon and Clark can take your maintenance efforts from preventive to predicative, from reactive to proactive through condition monitoring services.

Condition monitoring is the process of understanding your equipment’s current and trending characteristics that indicates the health of your asset.

Facilities that can Accommodate your Repair Needs

Brandon and Clark has several motor repair facilities spanning across the Panhandle of Texas, to the Permian Basin, and over to East Texas. We are equipped with:

- In-house machine and fabrication capabilities

- Vertical mill

- Engine lathe

- 50 Tons of hoisting

- Dynamic balancing

Clean, climate controlled winding facility - 96” VPI (Vacuum Pressure Impregnation) system

- sRMFA Rotor tester (Surface Rotor Magnetic Field Analysis)

- Critical motor storage

- Controlled pyrolysis oven

- Transportation and emergency services

Controlled Burn Out Oven

In order to provide the very best motor repair, rewind or rebuild, you must first begin with the cleanest motor possible. To achieve these results the removal of old varnish, paint and insulation must take place. Brandon and Clark is equipped with a fully controlled pyrolysis cleaning, or “burn out”, oven that allows us to easily and quickly remove old material in a manner that is safe for the equipment and the environment.

- Safely strips the stator and parts without damage

- Fire prevention

- No pollution

- Large capacity

- Efficient

- Automatic controls to regulate the temperature

Schedule a Shop Tour! We'd love to show you around!

Choosing a motor repair facility that is qualified for motor repair is one of the most important decisions you can make when caring for your equipment.

Question is how do you choose or qualify a repair facility? One way is to listen to manufacturer’s recommendations. Brandon and Clark has been identified by several motor manufacturers as a chosen warranty service and repair provider.

Electric Motor Training

Proper motor installation and maintenance will ensure that your equipment will run efficiently and meet its life expectancy.

Brandon and Clark will help guide and train you to identify areas that you can apply to your maintenance processes.

Motor Base Modifications