On-Site Support for your Electric Motor Service Needs

On-Site Repair and Service

Responsive Emergency Services. Understanding that industry does not close in the evening or on the weekend, Brandon and Clark maintains a manager on call with the required support staff 24-hours per day, 7 days per week, 52 weeks per year at all locations.

Maintaining the Health of Your Motor

- In-Field Repair and Testing

- Ensure Proper Alignment and Balance

- Dry Ice Cleaning

- Engineering Services to Identify and Prevent Failure

- Motor Base Modifications

Watching for Trends

Vibration Analysis

All rotating equipment vibrates to some degree, the key is to monitor the equipment and take action before any serious damage can become an expensive problem. Vibration in electrical equipment can be caused by imbalances in the rotating parts, uneven friction, the meshing of gear teeth, bearing wear and a number of other causes.

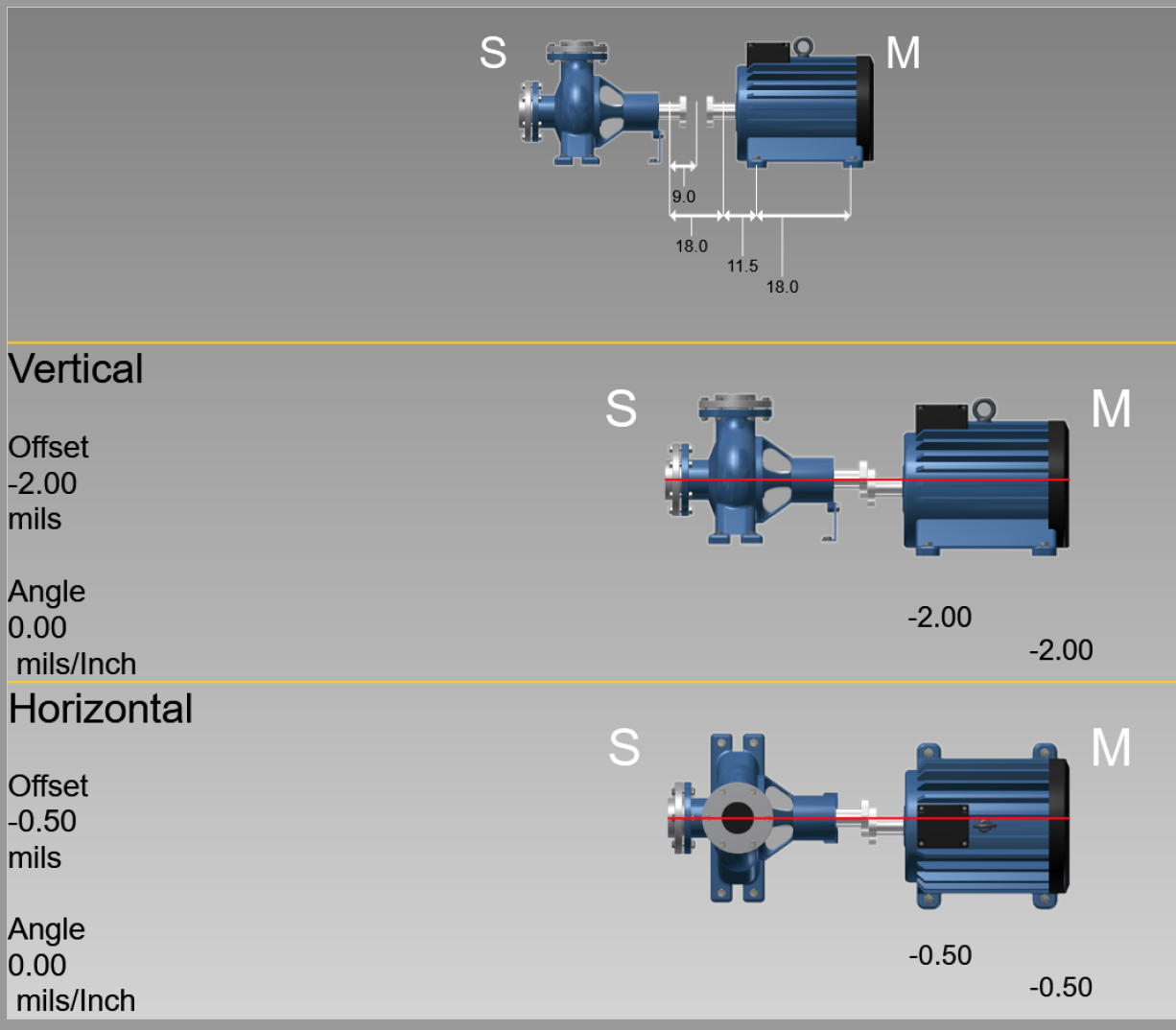

Laser Alignment

The proper alignment of coupled machinery is crucial to the performance and efficiency of the motor and the attached piece of equipment. Misaligned machinery are more likely to experience seal and bearing failure and excessive vibration all resulting in damage to the equipment, production loss and downtime. A misalignment can be detected during routine preventative maintenance such as vibration analysis.

Brandon and Clark performs both alignment and vibration services on all motors we install back into the field.

Dry Ice Cleaning

Dry ice blasting is similar to sand blasting, plastic bead blasting, or soda blasting where a medium is accelerated in a pressurized air stream to impact a surface to be cleaned or prepared. But that’s where the similarity ends. Instead of using hard abrasive media to grind on a surface (and damage it), dry ice blasting uses soft dry ice, accelerated at supersonic speeds, and creates mini-explosions on the surface to lift the undesirable item off the underlying substrate.

Benefits to Dry Ice Cleaning:

- It is a non-abrasive, nonflammable and nonconductive cleaning method

- Dry ice is environmentally-friendly and contains no secondary contaminants such as solvents or grit media

- This method of cleaning leaves no runoff which helps to reduce your companies carbon footprint and it is FDA, EPA and USDA approved

- This cleaning method is approved for use in the food and beverage industry

- Dry ice allows most items to be cleaned in place without time-consuming disassembly, most items can even be cleaned onsite since there is no hazardous runoff.

- This method of cleaning can be used without damaging active electrical or mechanical parts or creating fire hazards

- Dry ice blasting can be used to remove production residues, release agents, contaminants, paints, oils and biofilms

- Dry ice can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling

See for yourself the dramatic difference that dry ice blasting makes:

Before

After

Motion Amplification

Motion amplification is a service that utilizes patented technology to measure deflection, displacement, movement and vibration of equipment and structures not visible to the human eye. Utilizing video camera technology in conjunction with a one-of-a-kind software and processing algorithms we are able to extract meaningful data that solves problems. This technology turns every pixel in the camera’s view into a sensor capable of measuring vibration or motion with unparalleled levels of accuracy.

With motion amplification, not only can you see a problem, you will often times also see the solution because you now can visualize the root cause.

Motor Base Modification

With our Motion Amplification technology, often times we find that a problem with a motor is due to poor motor bases. Not having a good foundation will cause alignment and vibration problems down the road.