Complete Air Compressor Services

Getting air to where you need it

Air Pipe Installation Services

Getting air to where you need it is key to an efficient and profitable operation. Ensuring that air is available where you need it is a service that Brandon and Clark can provide. Using the best solution in air pipe, we will help to get your desired psi all throughout your facility and at each end device.

What's Air Costing You?

Stop Waisting Money

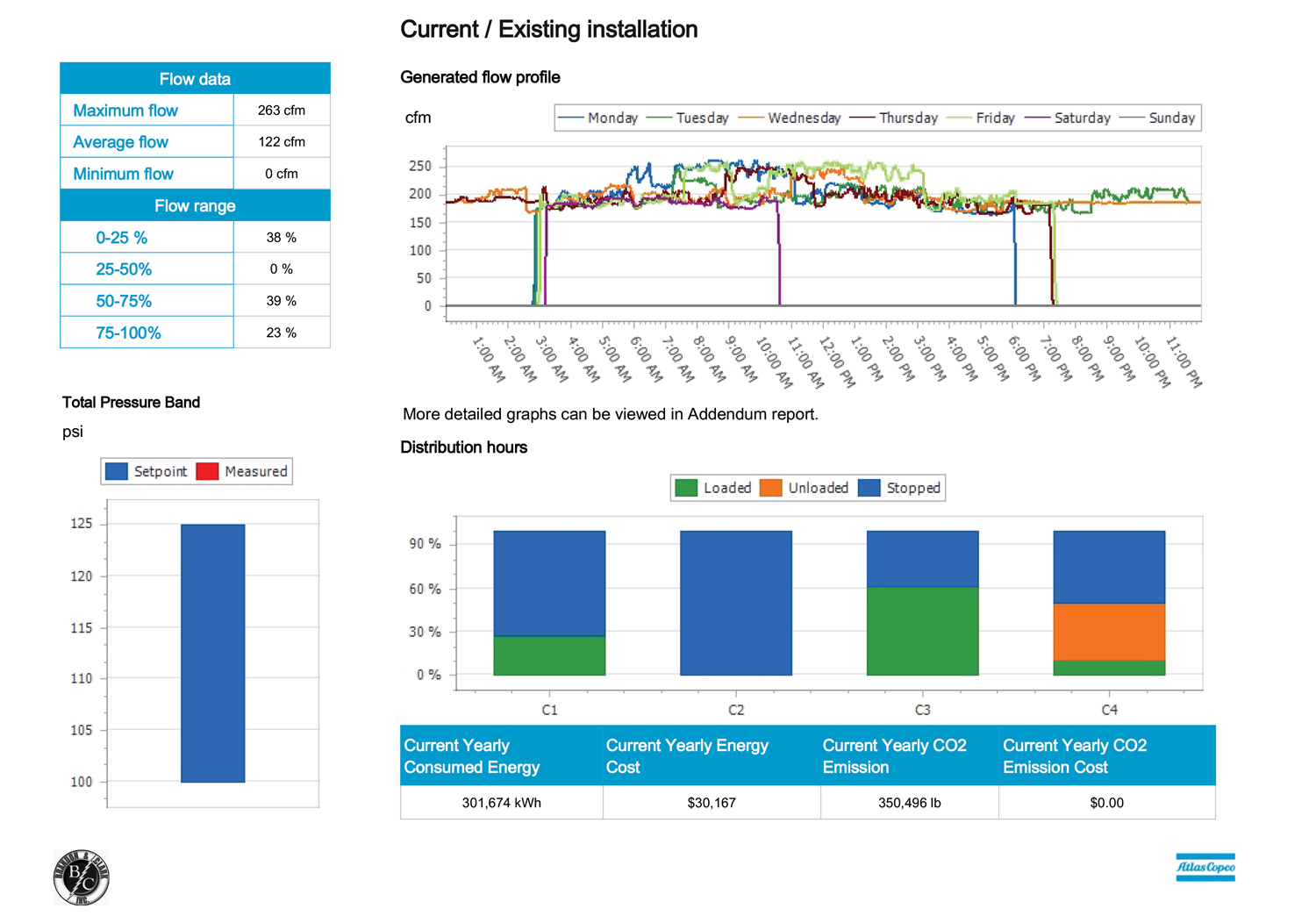

Chances are you are losing air somewhere within your plant or facility and air loss = money loss. Performing an Air Audit will quantify exactly how much energy is being used while production is underway. Often times, these results can be astounding!

An air audit service provided by Brandon and Clark, will determine:

- A baseline of energy use

- Peak and off peak usage in date and time format

- Brandon and Clark will offer suggestion to help improve the efficiency of your system and reduce costs

- Simulations within our auditing tool will tell you exactly the expected outcome if recommended changes are made and the expected payback time

We Offer an Wide Range of New Dryers and Air Compressors

Reciprocating

Oil Free

Oil/Water Separators

Medical Grade Air

Custom Skid Packages

Vacuum Pumps