On-Site Support for your Air System Needs.

On-Site Routine Maintenance and Installation Services

Brandon and Clark performs a thorough analysis of your air system’s equipment during each service call. Routine service is scheduled on a weekly, monthly, quarterly and annual basis that is in accordance with the manufacturer’s recommendations.

On-Site Service Checklist

Detailed Equipment Record Keeping:

- Discharge Temperature

- Line Pressure

- Sump Pressure

- Oil Pressure

- Oil Filter DP

- Load/Unload

- Amp Draw

- Voltage

- Dryer Dewpoint

Inspection:

- Oil Levels

- Air Filters

- Control Systems

- Control Panel

- Inline Filtration

- Tank Assembly

- Pressure Relief Valve

- Fan Assembly

- Belts/Coupling

- Air/Oil Leaks

- Electrical Connections

- Enclosure

Service Performed:

- Change Oil

- Change Oil Filters

- Change Air Filters

- Change Separator

- Lube Motor Bearings

- Drain Condensation

- Oil Sample

- Clean Aftercooler

Any other areas of observation or of concern is noted and then discussed with the customer to create an action plan.

Installation Services

Air Piping Installation

You need an air piping system that is void of leaks and distributes air exactly where you need it with the desired amount of psi!

Look no further than the solution provided and installed by Brandon and Clark.

Fast Installation Time

- Compression style fittings make installation simple

- Aluminum piping is easy to cut and lift

- O-ring seals ensure a leak free system

- No gluing, threading, or soldering

- Installs in half the time as some traditional methods

Diverse

- Install in small shops to industrial plants

- Connect to any existing piping system

- Expand or modify the system with ease

- No corrosion in the pipe and fittings means longer tool life

- Cools hot compressed air quickly for better filter performance

Energy Efficient

- Smooth inner wall and free flowing fittings lower compressed air costs

- Sealed connections means your compressor run time is less

Air Leak Detection Services

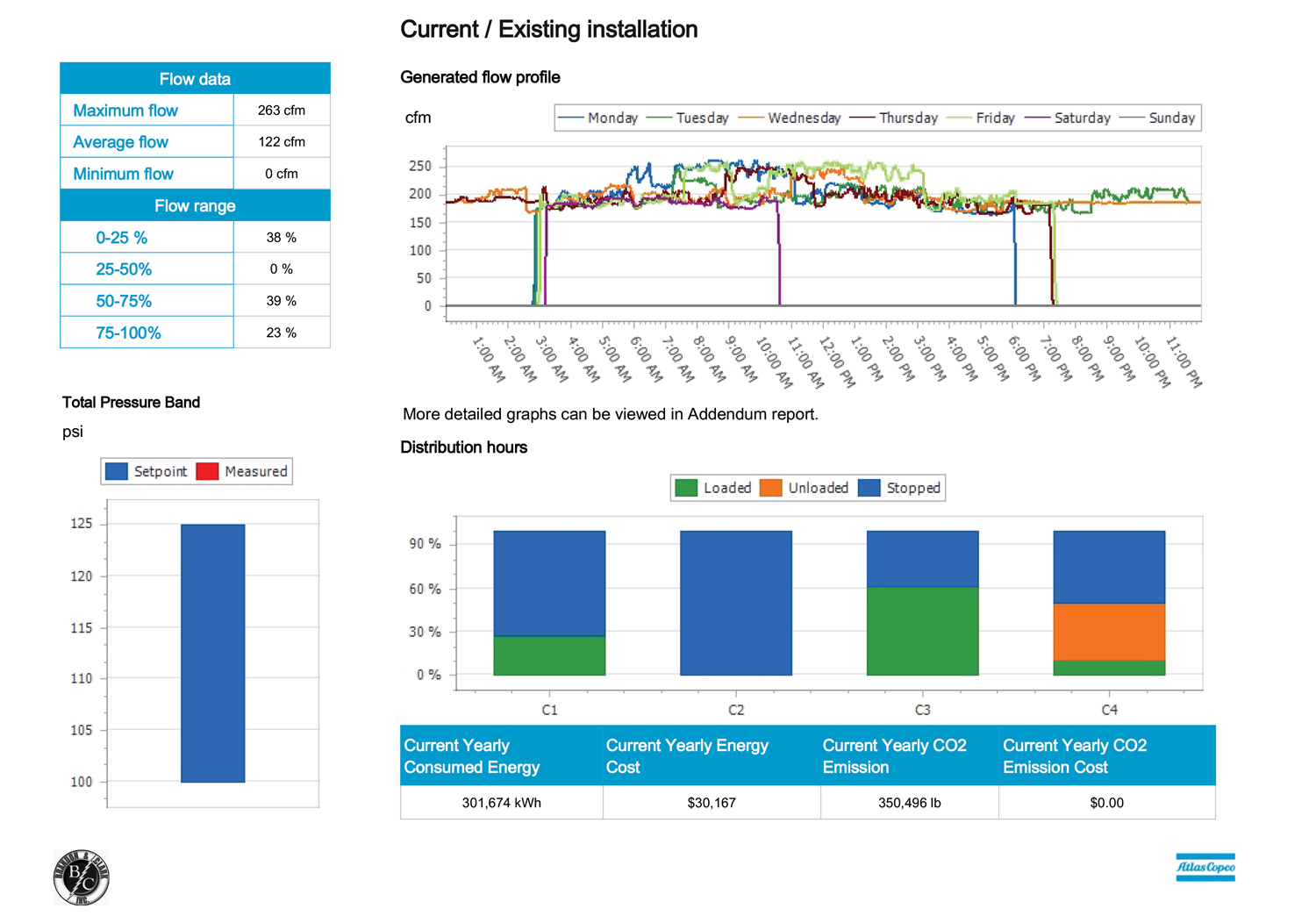

Chances are you are losing air somewhere within your plant or facility and air loss = money loss. Performing an Air Audit will quantify exactly how much energy is being used while production is underway. Often times, these results can be astounding!

An air audit service provided by Brandon and Clark, will determine:

- a baseline of energy use

- peak and off peak usage in date and time format

- Brandon and Clark will provide suggested changes to improve the efficiency and reduce costs

- simulations within our auditing tool will tell you exactly the expected outcome if recommended changes are made and the expected payback time.

Air audit sample report

Oil and Filter Service

It’s critical to keep dust and debris out of the internal components of your machine and the best way to do so is through routine oil and filter maintenance.

Good maintenance will ensure:

- full life of the machine

- prevent contamination – keep oil and air separate and clean

Brandon and Clark uses genuine replacement parts to service your machine. Doing so will help to maintain its warranty and we follow manufacturer guidelines for best maintenance practices.

Atlas Copco’s UD+ oil coalescing filters efficiently reduce oil aerosol, wet dust and water drops in your compressed air stream to protect your investment, equipment and processes. The UD+, combines two filtration steps (DD+ and PD+) into one, a unique technology to meet the high-quality requirements of diverse applications and provide ultimate energy savings.

- Energy Savings

- Small Footprint

- Save Money

- Pure Air

- No Risk of Cracks in Filter Media